The world of food logistics is demanding and requires innovative solutions to ensure maximum efficiency. In one of our most recent projects, we were able to plan and install the energy center of a leading food logistics company. Two years after the installation, we are proud to be able to present the excellent condition of the system.

Why an energy center and not a cooling center?

An energy center offers both heating and cooling options, maximizing flexibility and efficiency. Our system comprises a large cold brine chiller that generates 800 kW of cooling, as well as a heat pump with 400 kW heating capacity and 200 kW backup cooling capacity. This enables dynamic energy distribution that is tailored to the specific needs of the business. All cooling generators are operated with natural refrigerant NH3 (R717).

The technology in detail

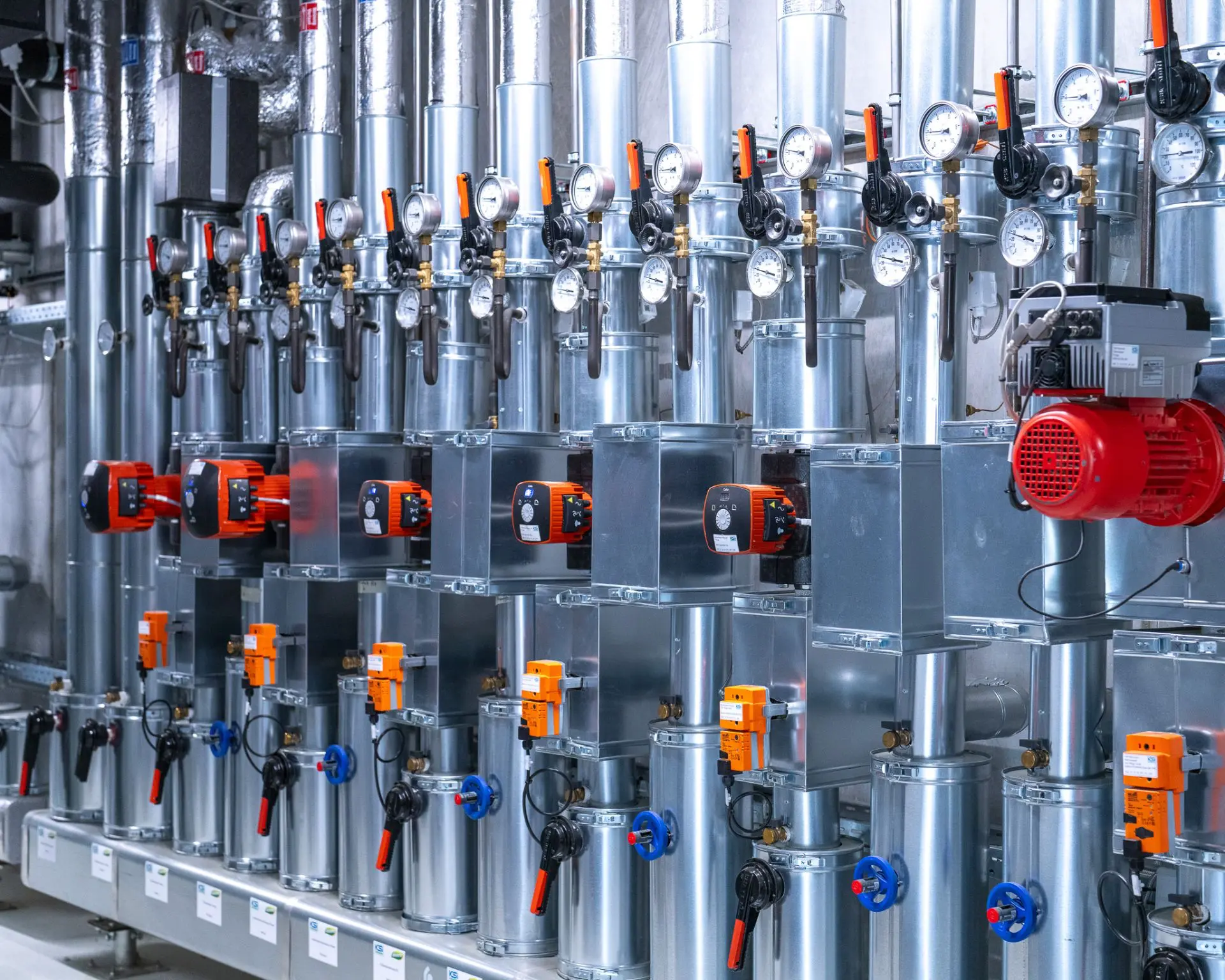

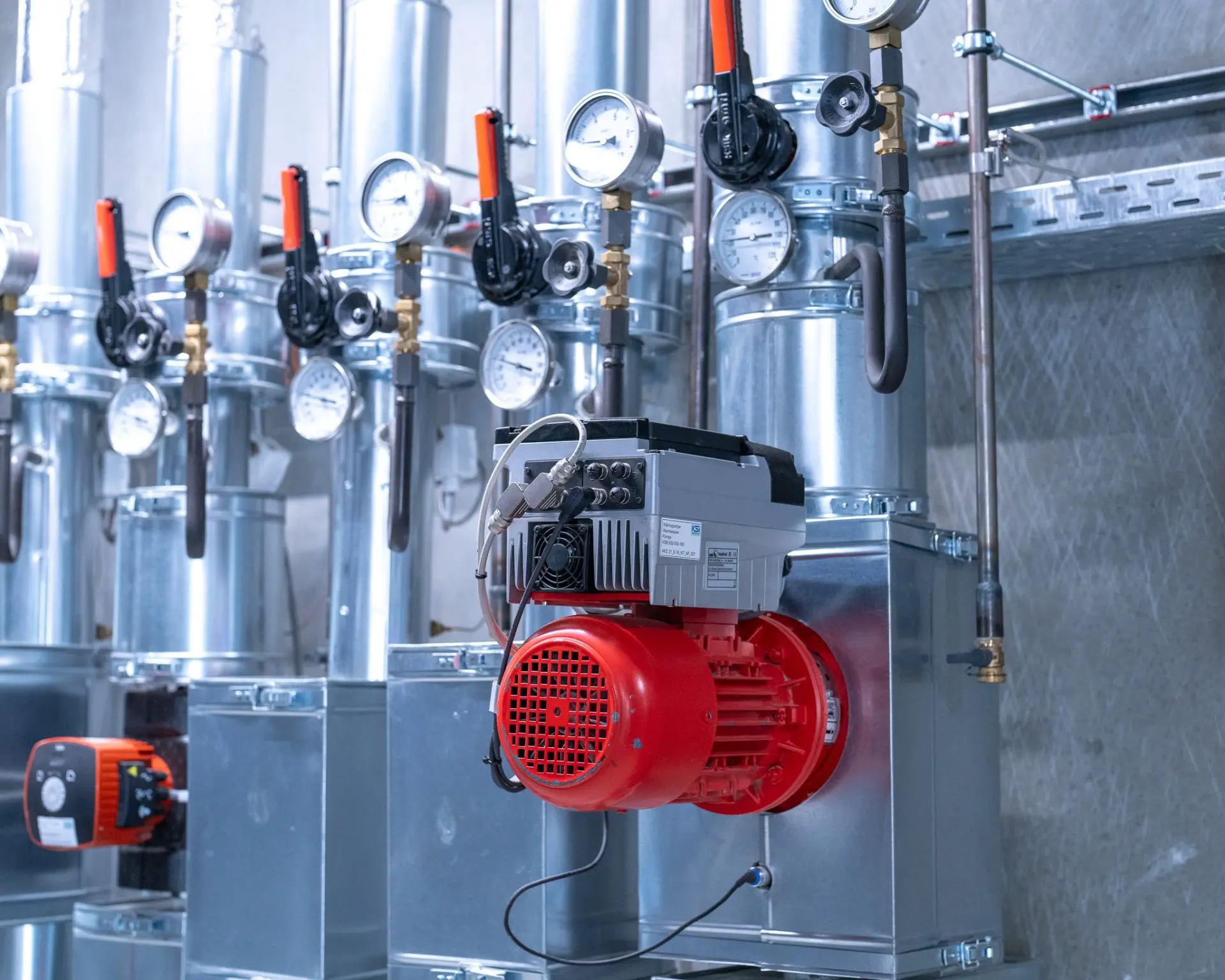

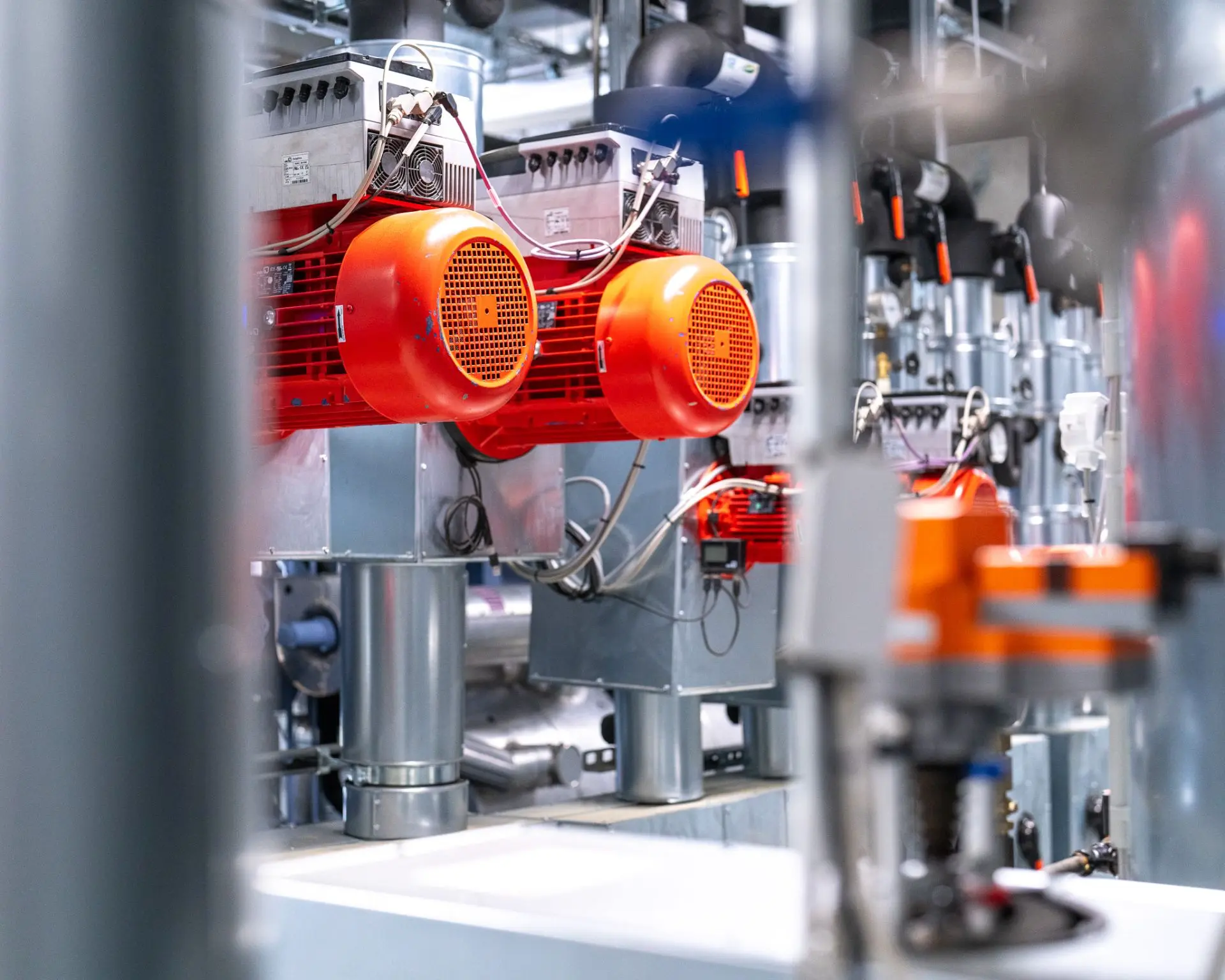

We paid attention to several aspects when planning and installing the energy center:

▶️ Cold and heat storage: Large buffer storage tanks ensure that both heat and cold are available as required.

▶️ Utilization of waste heat: Energy from the heat recovery system and the oil cooling system is collected and used to preheat water or to heat the offices.

▶️ Holistic approach: The system supplies both the production process and the office building with cooling and heating.

The new energy center offers numerous advantages:

▶️ High efficiency: Maximum energy efficiency is achieved by combining cooling and heat generation.

▶️ Redundancy and safety: Several buffer storage tanks and a redundant control system guarantee smooth operation.

▶️ Environmentally friendly: The use of natural refrigerants such as ammonia significantly reduces the environmental impact.

Challenges and solutions

The installation of the energy center was a challenging project, which we successfully completed despite numerous obstacles:

▶️ Lack of space: The technical center only offered limited space, so we had to implement a compact and efficient pipe routing.

▶️ Multi-storey installation: cables had to be laid over eight floors, which required precise planning and coordination.

Maintenance and service

Even after installation, we support the system with regular maintenance and service:

▶️ Remote monitoring: A Siemens-based system enables detailed monitoring and control of the system from a distance.

▶️ Preventive maintenance: By analyzing operating parameters, potential problems can be identified and rectified at an early stage.

Conclusion

Our project at this food logistics company shows that a well-planned and installed energy center can still be in excellent condition after two years.